Are you a “smart foundry?”

Held in Slovenia it highlighted the impact of:-

‘’Industry 4.0 – the fourth industrial revolution –will alter and shape our work, social and physical environment along with how we live and co-exist’’

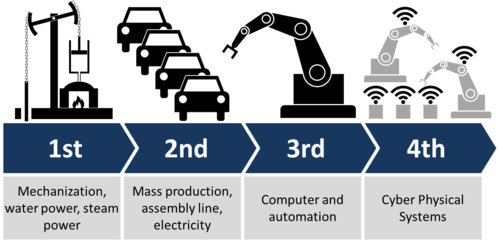

The fourth industrial revolution is the current trend of automation and data exchange in manufacturing technologies. It includes cyber-physical systems, the Internet of things and cloud computing.

Dr-Ing Christian Wilhelm – The managing director of BDG (the German Foundry Association) said: -

“Industry 4.0 cross links production processes and is already being used in many modern foundries. The issues of frontloading and copy protection are only two of the many aspects of the maximum co-operation between foundrymen and the design departments which is absolutely necessary for maintaining a competitive edge. We must Improve, Improve, Improve – it is a never ending story’’

Discussing the process of digitisation Dr-Ing Andreas Buhrig-Polaczek of Aachen University commented ‘’ For foundry processes, a high number of relevant data has to be taken into account – the measurement of technical data in an industrial environment is especially often not satisfactory. The idea of industry 4.0 is a step forward so a model gives you a forecast – predictive analysis. We need a constant process and constant parameters – all data has to interact.’’

A vision of the diecasting plant of tomorrow was given by Dr-Ing Kai Kerber of OskarFrench Gmbh & co ‘’Some technology is 40 years old he said so industry 4.0 has to be practical for existing equipment to enable old machines to work like new ones. We must let the IT environment get into engineering – the IT world has solutions that can help us.

For the full Conference report, you can subscribe to FTJ (Foundry Trade Journal here)

As the Global Leading Cast Metal Software Provider, SYNCHRO ERP IS the solution

For forty years, SYNCHRO ERP has been providing growth, innovation, and prosperity to the global metal casting manufacturer’s, SYNCHRO ERP is an Industry Specific Software Solution.

Chris Collins CEO of SYNCHRO commented; -

“The cloud enables manufacturing companies to deliver ERP software to customers, while eliminating excess hardware and maintaining control over system integration. As a result, the complexity of providing the highest level of customer service is reduced significantly. Accessibility from any location - rather than being restricted to installations on individual computers, an application can be accessed from anywhere with an internet enabled device”

Be a “Smart Foundry” contact SYNCHRO ERP

- Share this:

- More news:

-

Always learning

Back safe and warm in Synchro Towers after a trip up to my old hometown of Worcester for a four day training course. Over in the support team we don't have the life on the road of our Global Training and Implementation Team, and leaving the family at home to head out can be tough, but it's vital to keep up to date with the current standards and features.

-

New Team Member!

‘It’s getting harder to tumble out of bed, stumble to the kitchen and pour myself a cup of ambition.’